Thursday, March 8, 2007

What I Should Have Said in Less Than Two Minutes

Gentlemen, you are likely eager to bail out of here after the foregoing endless sets of slide presentations. Today I have only virtual slides. Slide one lists eight nuclear power plants that have applied ultrasonic fuel cleaning. Slide two shows the ultrasonic fuel cleaning equipment. Slide three has two photographs of fouling on nuclear power plant fuel rods. Slide four shows that with fouling, light water reactors have operated with fuel cladding surface temperatures in the range of 1200 degrees Fahrenheit and above (instead of the range of 550 to 600 degrees Fahrenheit that is the design basis for long term operation). Slide five is fantastic and non-existent; it shows the growth of Zirconium dioxide scale and also the increase in dissolved oxygen concentration in the cladding with time at six operating temperatures: 600, 800, 1100, 1500, 2000 and 2500 degrees Fahrenheit. To produce slide five, more experiments are needed with Zircaloy cladding, as called for by the AEC Commissioners decades ago.

Wednesday, March 7, 2007

A Real Small Break LOCA that could not be isolated

We completed fabrication and crude shakedown testing of the loop at Argonne, Chicago, and shipped the gear to NRTS. With expert assistance and design improvement by key personnel from Phillips Petroleum Company, the operating contractor for MTR, installation and startup of the equipment proceeded in record time. So the loop was operating with the prototype Nautilus fuel in place, when I had my baptism in managing an accident. A 1/4 inch diameter sensing line at the main flow metering orifice severed and blow down from 2500 PSI and 570 degrees F. began. I was at the control panel and the first indication of trouble was a loss of flow signal that let to switching of the primary pump to a standby pump, followed immediately by a scram (fast shutdown) of the MTR.

I very quickly knew where the break was, and I knew that it could not be isolated. I decided that the best approach would be to allow the primary pumps to automatically shift from A to B to C and back to A, etc., as the blowdown proceeded. An option would have been to turn off the pumps, but that would have led to a real loss of cooling for the prototype Nautilus fuel while it still had a relatively high level of decay heat. Of course, this option was not an option forever. At some point, the pressurizer would be empty and voiding and real loss of flow would quickly follow.

My first step was to turn on a low capacity piston pump that delivered about one gallon per hour to the loop. I valved this flow to the liquid level reference sensing standpipe for the pressurizer. I knew that the loop was operating with a concentration of dissolved hydrogen for corrosion control. I also knew that the cold reference sensing line acted as a cold thumb and the the hydrogen concentration on the standpipe would be at saturation for 2500 PSI and its temperature of under 100 degrees F. And I knew that as pressure was reduced during blowdown the hydrogen would begin to outgas in the standpipe and that water would thus be bubbled out of the standpipe. The liquid level signal would then be false and the pressurizer would be empty even though the instrumentation would indicate otherwise. I also knew that the modest flow into the standpipe would not upset the accuracy of the calibration of the level sensing system.

So, I allowed the loop to blow down and depressurize, and as the level approached 10 percent of full, in quick order I proceeded as follows: I turned off the primary pumps. Next, with assistance from Fred McMillan of Phillips Petroleum Company, I isolated the in-pile pressure tube assembly from the main loop (two valves) and then opened the cooling of the in-pile assembly to once-through cooling by process water (two more valves).

Of course, it is not always great for one's career to be on the scene of an accident. And it makes little difference if one's moves were somewhat lifesaving. A few months later I was back at the home office at Argonne, Chicago. At one point I was asked what good I thought a gallon per hour of injected flow would do in the blowdown situation. Well, I did not answer.

Decades later, the value of a degassed reference standpipe (or the safety problem with a hydrogen saturated standpipe) was not recognized by some very highly paid consultants as well as the equipment suppliers of huge nuclear power plants.

Saturday, March 3, 2007

Blind faith in single tube tests in the production of TRACE

MEMBER ABDEL-KHALIK: But philosophically, if you had a perfect code, and you understand the physics, then it doesn't matter what the scale is because you're verifying phenomena. And therefore, by this process, you're essentially saying the code is nothing more than an empirical fitting tool for the experimental data. Is that true?

MEMBER BANERJEE: It cannot predict new phenomena.

MEMBER ABDEL-KHALIK: Because you are limiting the range of applicability of the code, essentially, to a rather narrow range around where the experiment is. So the code, you philosophically by doing this, you're viewing the code as nothing more than an empirical fitting tool.

MR. BAJOREK: I think that's an accurate statement.

MEMBER POWERS: Do you really want to say that though? I think that's what he was getting at.

MEMBER BANERJEE: It's not predictive of new phenomena.

MR. BAJOREK: That's the -- these codes are not based on first principles. They are based on and held together by closure relations which are based on sub-scale experiments. A lot of those correlations come from single tube tests and you are using that at faith when you start to look at larger and larger scales. Assessment helps to benchmark and let you know whether those correlations are truly applicable with those other conditions but going back to the experiments, we all in integral tests in particular, you want to try to establish a basis for that system global-wide behavior and is it going to behave much like you'd expect in something with much larger scale. But the smaller scale test, that's all you have to run the full test.

MEMBER BANERJEE: As we come to full scale tests.

MR. BAJOREK: If we had full scale tests the --

MEMBER BANERJEE: The assemble system, we can do it in components.

MR. BAJOREK: Components, yes. That's all

The complete transcript from which the above was extracted may be found at:

http://www.nrc.gov/reading-rm/doc-collections/acrs/tr/fullcommittee/2007/ac020107.pdf

However, all of the single tube tests, and also the larger scale tests were conducted with clean (unfouled) heat transfer surfaces. Faith in those tests is blind faith. More later on this.

Wednesday, February 28, 2007

It is not a TRACE; it is a mamouth SMOKESCREEN

The entire transcript may be viewed at:

http://www.nrc.gov/reading-rm/doc-collections/acrs/tr/subcommittee/2006/th120506.pdf

Going back to January 11, 2001, The ACRS issued a letter, Issues Associated With Industry-Developed Thermal-Hydraulics Codes. It is a lengthy tome with a very lengthy appendix.http://www.nrc.gov/reading-rm/doc-collections/acrs/letters/2001/4781926.html

The appendix includes the following section; I am quoting only the heading and the last sentence:

4. Codes have evolved, but the development process is hard to trace.

This situation supports the need for the staff to have its own code and to maintain a clear record of why design choices were made in its development.

Now, the TRACE racket has been proceeding under various guises for decades. Fortunes have been cast to the winds, not only in the software extravaganzas, but in the vast array of American as well as international test programs. The connections and relevance of the test programs to TRACE is obscure at best. The most recent disclosure of a link between testing and TRACE is from Staudenmeier in his slide presentation to the ACRS Thermal-Hydraulics Phenomenon Subcommittee on February 15, 2005. Two slides follow:

The four test series in the slide above are a very small sample of the vast test programs that have been conducted, largely on the basis that they were needed for code development and proof testing. There is no mention of extensive LOFT and SPERT projects that were conducted decades ago at the presently named Idaho National Laboratory. This 2005 transcript may be viewed at:

The four test series in the slide above are a very small sample of the vast test programs that have been conducted, largely on the basis that they were needed for code development and proof testing. There is no mention of extensive LOFT and SPERT projects that were conducted decades ago at the presently named Idaho National Laboratory. This 2005 transcript may be viewed at:

http://www.nrc.gov/reading-rm/doc-collections/acrs/tr/subcommittee/2005/th021505.pdf

There is no mention of the "... more than 50 tests ..." that are discussed in my entry of February 20, 2007. Returning to that matter, here are some extractions from the NRC Memo that predates the Staudenmaier slide show by almost one year.

Memo to Matthews/Black-Technical Safety Analysis of PRM-50-76, A Petition for Rulemaking to Amend Appendix K to 10 CFR Part 50 and Regulatory Guide 1.157 - ML041210109. 18 pagesApril 29, 2004

Mr. Leyse states that:

“Petitioner is aware that more experiments with Zircaloy cladding have not been conducted on the scale necessary to . . . overcome the impression left from run 9573.”

In the above Memo, the NRC responded to its quote of Leyse as follows:

In the early 1980's, the NRC through Pacific Northwest Laboratories (PNL) contracted with National Research Universal (NRU) at Chalk River, Ontario, Canada to run a series of LOCA tests in the NRU reactor. More than 50 tests were conducted to evaluate the thermal-hydraulic and mechanical deformation behavior of a full length 32-rod nuclear bundle during the heatup, reflood and quench phases of a large break LOCA. Two tests were initially selected (References 17 and 18) for COBRA/TRAC (Reference 19) simulation to assess the applicability of that code. The NRC is reviewing the data from this program to determine the value of using it to assess the current generation of codes such as TRAC-M (Reference 20), now renamed TRACE.The full ACRS meets March 8, 9 and 10, 2007 and will include the preparation of several ACRS reports in open sessions. One of the reports is "TRACE Thermal-Hydraulic Analysis Code." It will be interesting to find out what ACRS thinks about this chaotic situation.

Saturday, February 24, 2007

Suppose I had false memories

So let us suppose that near the west coast there was a nuclear test reactor of sorts. And the downtown office sends a front man to Idaho to attend some SL-1 explosion briefings. Upon his return, if he went, he comes out in the country and gives us a sanitized briefing at the reactor of sorts (ROS). He describes the central control rod at SL-1 and before he gets to his next sentence, a sneering commenter might have bellowed out, "It would take a team from Argonne to put a control rod right in the center of that core."

Now we can move ahead a few years. The ROS might have been built with control rods that used boron stainless as structural material as well as poison. The control rod structure could have cracked after moderate use, leading to binding and other bad scenes. So, a cadmium assembly could have been designed that would have superior life and equivalent control strength (with thermal neutrons, black is black). For a bit of further background, the ROS might have had six control rod assemblies with fuel followers, and if these assemblies existed, they were similar to the assemblies of the Engineering Test Reactor ETR that was in Idaho. The ETR poison sections were about three feet long and they included fuel followers so that fuel was added to the control rod location as control rods were withdrawn.

So, a new cadmium assembly might have been built, but how to test it for worth? The easiest thing would be to place it in the very center position of the ROS, go critical, shut down, remove it, and replace it with an old boron assembly and go critical again. Then a comparison of the positions of criticality would be a great proof test.

But there might have been a restriction on such a procedure because the amount of reactivity (plus or minus) that was allowed in the center of ROS might have been limited by its operating license, it it had such. However, under an AEC rule, 50.59, it might have been stipulated that the restriction on reactivity only applied to long term operations and not a simple field test of only several minutes at the most.

So, such a comparison might have proceeded. And if it did proceed, the sneering commentator of the second paragraph above might have had the task of predicting the amount of withdrawal of the six control rods that would yield criticality. And if such a prediction was made, it might have been that criticality would be reached with about half of full withdrawal, about 18 inches.

If the test proceeded, it might have been found that criticality was not reached as predicted. And then a guy in the control room might have telephoned the sneering commentator (who could have been elsewhere). The sneering commentator might have provided assurance that the situation was no big deal, that with such an unusual geometry with such a vast amount of poison in the most reactive location in the core, an accurate prediction was likely out of the question.

So, the test may have proceeded. And if it did, the careful slow withdrawal of the bank of six control rods might have proceeded with several stops along the way to criticality. And criticality might have been reached with the gang withdrawal at 33 inches out of the maximum 36 inches that was possible with the ETR design. And that would have been very interesting since fuel followers would have added to the reactivity worth of the center of the core. And if the test had proceeded it might have been found that the cadmium section also led to 33 inches of gang withdrawal. After all, black is black.

And so, if in the game of inserting the control rod in location E-5, going critical, shutting down, removing the control rod, placing the new design, going critical, shutting down, removing the new design; if, then it might have been very fortunate that nothing happened that would have made SL-1 look like a ladyfinger.*

*During the mid 1930s, if a kid could get his money onto the counter, he could buy firecrackers. If he saved up, he could buy three ten inchers for a dime. For a nickel he could by a package of zillions of ladyfingers. Ladyfingers were weak little things that would damage nothing even if held held between the kid's fingers.

Tuesday, February 20, 2007

Mr. Chairman, tell me about those more than 50 tests, please.

Of course, these entries are brief, however, a total disclosure of the facts would be quite lengthy. Anyway during the past eight years or so, I've submitted several Petitions for Rulemaking to the NRC and they have all been denied. But the record is there, including letters of derision from various vendors, operators and lobbyists. (More on all that in future entries to this blog.)

In the early 1970's there was a lengthy set of hearings run by the AEC in the matter of emergency core cooling systems. About the best assertion by the Commissioners is that more tests with Zircaloy are necessary to "... overcome the impression left from run 9573."

One of my petitions was docketed as PRM-50-76 and the NRC spent a few dollars on a document of refutation, ML041210109, April 29, 2004.

The following is extracted from that document:

Mr. Leyse states that:

"Petitioner is aware that more experiments with Zircaloy cladding have not been conducted on the scale necessary to ... overcome the impression left from run 9573."

In the early 1980's, the NRC through Pacific Northwest Laboratories (PNL) contracted with National Research Universal (NRU) at Chalk River, Canada to run a series of LOCA tests in the NRU reactor. More than 50 tests were conducted to evaluate the thermal-hydraulic and mechanical deformation behavior of a full length 32-rod bundle during the heatup, reflood and quench phases of a large break LOCA. ... The NRC is reviewing the data from this program to determine the value of using it to assess the current generation of codes such as TRAC-M, now renamed TRACE.

Well, it has been almost three years since our NRC issued that analysis, but I have yet to find documentation of those more than 50 tests from the early 1980's. Moreover, there is no reference to those "... more than 50 tests ..." in the great "Compendium of ECCS Research for Realistic LOCA Analysis," NUREG 1230, December, 1988. And, if the NRC has ever gotten around to determining the value of whatever meager data may exist, they have likely found that it has no value although they have not openly documented that.

Repeating, the NRC staff issued its document of refutation, ML041210109 on April 29, 2004. Almost one year later, the NRC notified me of its denial of petition for rulemaking (PRM-50-76). In her cover letter, (ML052220454), the Secretary of the Commission, Annette L. Vietti-Cook, a designated authority in these matters, informed me:

Contrary to your assertion that there has not been appropriate testing to address the issues raised by run 9573, the NRC has continued to study complex thermal hydraulic effects on ECCS heat transfer processes during accident conditions related to LOCAs consistent with Commission direction. As part of that initiative, the NRC funded more than 50 Zircaloy clad nuclear fueled bundle reflood experiments at the National Research Universal (NRU)reactor. These experiments evaluated fuel rod and heat transfer behavior but did not include metallurgical examination to evaluate oxidation behavior. The NRC is continuing to conduct and evaluate experimental and analytical programs on fuel cladding behavior.

Maybe the Secretary is using tricky language. She says the NRC funded more than 50 tests, but in contrast to the report of her staff, she does not assert that more than 50 tests were conducted. In any case, there are no more than 50 tests in any record, and the NRC is practicing fraud and falsification.

Bernie Ebbers of Worldcom fame disclosed that he knew what he did not know and that he knew nothing about technology or financial accounting. He is in jail and will likely be there for for a long time!

Monday, February 12, 2007

Regulation by myth

General Electric (the fuel vendor) calculated that the cladding surface temperatures exceeded 1200 F in localized areas.

and

The team noted that the thermal resistance of crud is not normally sufficient to cause cladding temperature increases consistent with those observed during Cycle 8. In most circumstances, "wick boiling" occurs within the crud. That is, capillary coolant channels within the crud deliver coolant to the cladding surface. Steam then escapes from the cladding surface in chimney type plumes. This is a fairly effective method of heat transfer. However, in some instances the capillary coolant channels can become clogged, creating a static steam blanket on the cladding surface. Steam is an exceptionally good thermal insulator. This is the process that caused the very high cladding surface temperatures and ultimately resulted in fuel cladding failure.

Now, "wick boiling" is a fabrication from somewhere, and the above quote is a myth. So, I sent an e-mail to Chairman NRC advising him to get that paragraph eliminated. I e-mailed, "Indeed that entire paragraph should be deleted in a corrected report. The team should study report ANL 6136."

I should also have told the Chairman to have the inspection team study McAdams, Heat Transmission, 1942, Chapter X, HEAT TRANSFER TO BOILING LIQUIDS. On page 316, "The small amount of scale necessary to reduce a high coefficient by a substantial amount is not generally realized."

Maybe the NRC thinks that crud is not scale!

Saturday, February 10, 2007

"... continued operating risks were accepted ..."

The title, "... continued operating risks were accepted," is extracted from the first of the two Oxenford papers. My contention is that the "operating risks" are safety risks. At least one "expert" has testified to the NRC's ACRS that severe fouling is not a safety matter; that severe fouling is merely an economic consideration. That testimony was presented a few years prior to the Oxenford papers. A skilled sanitizer from the nuclear power lobby would have changed Oxenford's "operating" to "economic."

Now, the above cited "expert" was (or is) not out of line with NRC thinking. In the enclosure with her letter to Entergy's Hinnenkamp on February 28, 2006, the NRC's Linda Joy Smith reports that her inspection team at River Bend found that crud during cycles 8 and 11, "... is of very low safety significance ... ." See NRC file ML060600503. I'll report further on this.

Monday, February 5, 2007

WHOOPS! A Clue to Fouling Elsewhere?

The above report is a fantastic disclosure, and I will be pleased to be corrected, but all of this seems to have gone on without any attention from our NRC.

The above view is from the Oxenford report page 13. It is very interesting that this 1999 data is first released 6 or 7 years later, and it is the first time anyone has openly disclosed that main condenser inleakage may be among the root causes of fouling.

The above view is from the Oxenford report page 13. It is very interesting that this 1999 data is first released 6 or 7 years later, and it is the first time anyone has openly disclosed that main condenser inleakage may be among the root causes of fouling. The above slide from Oxenford, page 16, is explicitly labelled, "After Chronic Condenser Leak." On page 4 of his June, 2006, white paper, Oxenford discloses, "Our concerns resurfaced in 1999 following fuel failures at the River Bend plant (admiralty brass condenser with deep bed demineralizers). We closely tracked the River Bend cause analysis. River Bend corrosion had high copper levels, but the failures were attributed to high iron levels in their corrosion layer. Based on Columbia being a low iron plant, no action was taken."

The above slide from Oxenford, page 16, is explicitly labelled, "After Chronic Condenser Leak." On page 4 of his June, 2006, white paper, Oxenford discloses, "Our concerns resurfaced in 1999 following fuel failures at the River Bend plant (admiralty brass condenser with deep bed demineralizers). We closely tracked the River Bend cause analysis. River Bend corrosion had high copper levels, but the failures were attributed to high iron levels in their corrosion layer. Based on Columbia being a low iron plant, no action was taken."Saturday, February 3, 2007

"It is a flame-front phenomenon ... ."

Please click on the

Please click on thehttp://www.inl.gov/relap5/rius/yellowstone/leyse.pdf

You will then view a set of 18 slides.

Today I'll discuss slide 16 and then slide 15. Slide 16 is below, followed by slide 15

Unfortunately, MacDonald did not present any photographs. If he had, they would very likely be similar to the photograph on my entry of January 21, 2007, in this blog. That test was conducted on December 11, 197o, or more than 10 years before the MacDonald report to the ACRS. The test of December 11, 1970, became known as run 9573. During 1973, the Atomic Energy Commission held a series of hearings as they investigated the safety of nuclear power plants under accident conditions. The Commissioners were dismayed by the implications of run 9573 and the transcript of the proceedings includes the quote below in slide 15.

Unfortunately, MacDonald did not present any photographs. If he had, they would very likely be similar to the photograph on my entry of January 21, 2007, in this blog. That test was conducted on December 11, 197o, or more than 10 years before the MacDonald report to the ACRS. The test of December 11, 1970, became known as run 9573. During 1973, the Atomic Energy Commission held a series of hearings as they investigated the safety of nuclear power plants under accident conditions. The Commissioners were dismayed by the implications of run 9573 and the transcript of the proceedings includes the quote below in slide 15. It is interesting that as of today, over 33 years later, experiments with zircaloy cladding have not overcome the impression left from run 9573. MacDonald's report of the PBF test certainly does not overcome the impression left by run 9573. And the flame front phenomenon described by MacDonald has not been addressed in any of the months or years following his report; however, billion dollar models have been concocted.

It is interesting that as of today, over 33 years later, experiments with zircaloy cladding have not overcome the impression left from run 9573. MacDonald's report of the PBF test certainly does not overcome the impression left by run 9573. And the flame front phenomenon described by MacDonald has not been addressed in any of the months or years following his report; however, billion dollar models have been concocted.Friday, February 2, 2007

Further Notes on ULTRASONIC FUEL CLEANING Under CFR 50.59

The Westinghouse brochure that is referenced in my entry of January 27, 2007, lists the following eight sites that have applied ultrasonic fuel cleaning by the end of 2005.

- Callaway

- Catawba

- Ft. Calhoun

- McGuire

- Quad Cities

- South Texas 1 and 2

- Vogtle 1 and 2

- Vandellos

This Westinghouse brochure was recently updated during November 2006, therefore the list is very likely up to date.

Recent Patent in the Arena of Ultrasonic Fuel Cleaning

The U. S. Patent 7,134,441, HIGH THROUGHPUT ULTRASONIC CLEANER FOR IRRADIATED NUCLEAR FUEL ASSEMBLIES, that issued on October 14, 2006, is assigned to Dominion Engineering, Inc. The related provisional application, No. 60/398,726 was filed on July 29, 2002. Very likely the process changes that are thus covered have been applied in at least some of the eight plants listed above. Also, other process changes may be the subject of further patent applications that might now be under review.

Apparently Ultrasonic Fuel Cleaning Has Not Been Applied at River Bend

It is interesting that River Bend is not among the above list of eight plants in view of the extreme fouling that is documented in my entry of January 22, 2007, Fouling of Reactor Fuel at River Bend. Possibly the corrosion of the reactor fuel at River Bend has been so severe that the ultrasonic process would lead to unacceptable cracking of the cladding.

Thursday, February 1, 2007

A wild application of CFR 50.59, ULTRASONIC FUEL CLEANING

The above slide is from the EPRI slideshow, HISTORICAL HIGHLIGHTS, that first appeared on the web during 2005. The above highlight for 1999 is Ultrasonic Fuel Cleaning. However, the first public disclosure of this activity was likely the "CFR 50.59 SUMMARY REPORT FOR THE CALLAWAY PLANT, that was submitted by Callaway to the NRC on November 14, 2001, item RFR 19637. The NRC file code is ML013540440.

The above slide is from the EPRI slideshow, HISTORICAL HIGHLIGHTS, that first appeared on the web during 2005. The above highlight for 1999 is Ultrasonic Fuel Cleaning. However, the first public disclosure of this activity was likely the "CFR 50.59 SUMMARY REPORT FOR THE CALLAWAY PLANT, that was submitted by Callaway to the NRC on November 14, 2001, item RFR 19637. The NRC file code is ML013540440.

Saturday, January 27, 2007

Field Experience With Ultrasonic Fuel Cleaning

Go to GOOGLE for these references; enter ultrasonic fuel cleaning. By far the most informative is the first reference (above) Ultrasonic Fuel Cleaning at STP. This illustrates the apparatus and the results of field applications. This is a very valuable reference for Students of Nuclear Engineering as well as their faculty.

Go to GOOGLE for these references; enter ultrasonic fuel cleaning. By far the most informative is the first reference (above) Ultrasonic Fuel Cleaning at STP. This illustrates the apparatus and the results of field applications. This is a very valuable reference for Students of Nuclear Engineering as well as their faculty.

The two News Releases (above) from EPRI are revealing. The March 19, 2003, release is the first News Release of this activity. This activity proceeded without any safety review by the NRC. The second News Release, October 3, 2005, lists further applications. The third entry from AREVA NP describes their ultrasonic cleaning services with technology licensed from EPRI; this entry is continued below. The final entry (below) leads to an excellent brochure from Westinghouse.

Ultrasonic Fuel Cleaning

The above e-mail was sent to me by Region 4, NRC, in partial response to my inquiry about the application of ultrasonic fuel cleaning at River Bend Station (RBS). See my entry of January 22 for a view of fouled fuel at RBS. Apparently, ultrasonic fuel cleaning has never been applied at RBS, although it has been applied at several other nuclear power plants.

The above e-mail was sent to me by Region 4, NRC, in partial response to my inquiry about the application of ultrasonic fuel cleaning at River Bend Station (RBS). See my entry of January 22 for a view of fouled fuel at RBS. Apparently, ultrasonic fuel cleaning has never been applied at RBS, although it has been applied at several other nuclear power plants. It is interesting that this complex physical chemical process was reduced to practice and applied at several nuclear power plants without any review or authorization by our NRC. There has been no licensing action and there is therefore no documentation of licensing in the NRC's Public Document Room.

I'll have further entries on this matter. In the meantime, eager readers may get interesting background at the NRC website via an ADAMS search at "ML032810635"

Wednesday, January 24, 2007

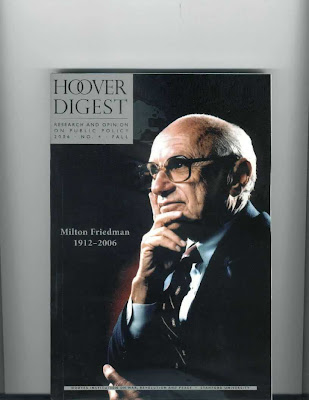

Milton Friedman and Price Anderson

Tuesday, January 23, 2007

Fouling in the Late 1950s

The Experimental Boiling Water Reactor (EBWR) operated at the Argonne National Laboratory during the late 1950s. The uranium fuel plates were clad with zirconium as illustrated in the drawing above. The adjacent photograph shows the fouling on a part of a fuel plate that was removed for destructive examination after about two years of service. The fuel plates became fouled with a mixture of aluminum and iron oxides. The source of the aluminum oxide was corrosion of aluminum filler pieces that were included in the structure of the reactor core. The thickness of the fouling ranged from 120 to greater than 200 microns. Of course, this fouling led to substantially higher fuel temperatures and this prevented extended operation of the EBWR at higher power levels. In general the impact of the fouling was only marginally considered and it was never included in evaluating the potential severity of accidents.

The Experimental Boiling Water Reactor (EBWR) operated at the Argonne National Laboratory during the late 1950s. The uranium fuel plates were clad with zirconium as illustrated in the drawing above. The adjacent photograph shows the fouling on a part of a fuel plate that was removed for destructive examination after about two years of service. The fuel plates became fouled with a mixture of aluminum and iron oxides. The source of the aluminum oxide was corrosion of aluminum filler pieces that were included in the structure of the reactor core. The thickness of the fouling ranged from 120 to greater than 200 microns. Of course, this fouling led to substantially higher fuel temperatures and this prevented extended operation of the EBWR at higher power levels. In general the impact of the fouling was only marginally considered and it was never included in evaluating the potential severity of accidents.Monday, January 22, 2007

Fouling of Reactor Fuel at River Bend

This was presented at the 2004 International ANS Meeting on LWR Fuel Performance, September 20, 2004. Apparently this was never formally reported to the Nuclear Regulatory Commission. At least, I have not found an LER or Inspection Report or other documents that cover this. Please compare this with my entry of January 20, 2007 (12:14 PM, not the later post on that date). More soon on this.

This was presented at the 2004 International ANS Meeting on LWR Fuel Performance, September 20, 2004. Apparently this was never formally reported to the Nuclear Regulatory Commission. At least, I have not found an LER or Inspection Report or other documents that cover this. Please compare this with my entry of January 20, 2007 (12:14 PM, not the later post on that date). More soon on this. An edit on February 14, 2007: An NRC inspection team finally caught up with this; see ML060600503, February 28, 2006 and my entry on this blog of February 12, 2007, Regulation by Myth,

Sunday, January 21, 2007

Double rubble, toil and trouble; Fire burn and ...

This rubble was produced in the test that has gained notariety as RUN 9573. It is briefly described in the entry of January 20, 2007. This was a 7 by 7 assembly of Zircaloy clad electric heaters that simulated nuclear reactor fuel under accident conditions. The assembly was heated to greater than 2200 degrees Farenheit and then quenched with cooling water. At the high temperatures the Zircaloy chemically reacted with the cooling water and that produced even higher temperatures. The severe reactions that led to the rubble also produced the fused clinker in the upper photograph. This clinker was lifted from the center of the assembly during the post test examinations. In the lower photograph note the white heater section where the Zircaloy sheath was completely removed by the intense chemical reactions at the very high temperatures.

This rubble was produced in the test that has gained notariety as RUN 9573. It is briefly described in the entry of January 20, 2007. This was a 7 by 7 assembly of Zircaloy clad electric heaters that simulated nuclear reactor fuel under accident conditions. The assembly was heated to greater than 2200 degrees Farenheit and then quenched with cooling water. At the high temperatures the Zircaloy chemically reacted with the cooling water and that produced even higher temperatures. The severe reactions that led to the rubble also produced the fused clinker in the upper photograph. This clinker was lifted from the center of the assembly during the post test examinations. In the lower photograph note the white heater section where the Zircaloy sheath was completely removed by the intense chemical reactions at the very high temperatures.Saturday, January 20, 2007

DOUBLE RUBBLE: Partial Disclosure

The above summary report, December 14, 1970, is partial disclosure relating to the photograph DOUBLE RUBBLE, TOIL AND TROUBLE.

For clarity the following key sentence and the related footnote is copied here: It appears likely that ignition of the Zircaloy grids led to high rates of heat input* at the elevation one foot above (and below) midplane and this caused overtemperature and failure of the heaters.

*The ratio of surface area to heat capacity for a Zircaloy grid is approximately 15 times that of a heater rod, hence Zircaloy-steam reactions can lead (to) steeper temperature ramps in the vicinity of a Zircaloy grid.

Fouled Fuel at a Nuclear Power Reactor

.jpg)

This is a photo of fouled fuel at a nuclear power plant. There are those who know where and when this was photographed. I have asked them to tell me where and when, but they have not disclosed this. This photo was also presented to the NRC's ACRS, but the transcript of the 2004 meeting does not disclose any details. So, if anyone out there is willing to disclose the facts, please come across on this blog or elsewhere!